Auto body shop direct repair restores vehicles to pre-accident condition through a meticulous process including inspection, debris removal, alignment, welding, priming, coating, and quality assurance. Timeline varies by damage complexity, part availability, and shop capacity, with advanced tools like CAD and robotic welding potentially reducing times. Shops optimize processes with cutting-edge tech, streamlined workflows, advanced estimating software, integrated services, and efficient inventory management for faster, reliable repairs.

In today’s fast-paced world, understanding the efficiency of auto body shop direct repair processes is crucial. This article delves into the evolving landscape of direct repair, exploring how long it takes to restore your vehicle to its pre-accident condition. We’ll break down the key factors affecting turnaround times and highlight strategies to optimize and streamline the process for greater efficiency in auto body shop direct repair.

- Understanding Auto Body Shop Direct Repair Process

- Factors Affecting Direct Repair Time Today

- Optimizing and Streamlining Direct Repair for Efficiency

Understanding Auto Body Shop Direct Repair Process

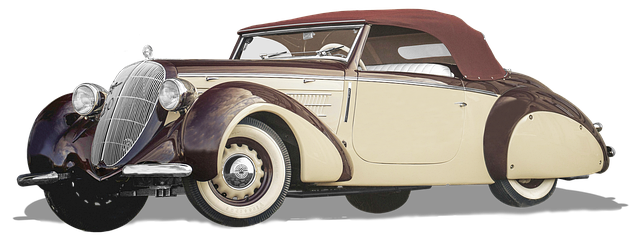

The auto body shop direct repair process is a streamlined approach to restoring vehicles, ensuring they return to their pre-accident condition. It involves several meticulous steps that require skilled technicians and advanced equipment. Initially, the damaged area is thoroughly inspected, and precise measurements are taken to create a detailed plan for the repair. This often includes sandblasting or sanding to remove any remaining debris or paint, followed by careful body panel alignment.

Technicians then proceed with specialized techniques such as spot welding, where small welds precisely join metal panels back together. After these repairs, the area is prepared for painting, which typically involves priming and coating to match the vehicle’s original finish. The final step involves quality assurance checks to guarantee that all repairs are up to standard before the car is released to its owner, ensuring a flawless restoration for both automotive repair and vehicle dent repair.

Factors Affecting Direct Repair Time Today

The timeline for auto body shop direct repair is influenced by several interconnected factors. One of the primary considerations is the complexity of the damage. Simple dings, dents, and scratches often take less time to rectify, while extensive repairs involving frame straightening, panel replacement, or significant structural damage can significantly prolong the process. The availability of parts also plays a crucial role; delays in acquiring necessary components can delay the repair schedule.

Modern auto body shops leverage advanced tools and techniques, including computer-aided design (CAD) and robotic welding, to streamline operations. These technologies enhance precision and efficiency, potentially reducing repair times compared to traditional methods. Additionally, factors like shop capacity, scheduling, and labor availability can impact turnaround times, with busier shops potentially facing longer wait times for customers. Given the ever-evolving nature of car repair services, understanding these variables is essential for estimating the contemporary direct repair duration in an auto body shop.

Optimizing and Streamlining Direct Repair for Efficiency

In today’s competitive market, auto body shops are constantly seeking ways to optimize and streamline their direct repair processes for maximum efficiency. By implementing cutting-edge technologies and adopting streamlined workflows, shops can significantly reduce turnaround times without compromising on quality. This includes utilizing advanced estimating software that automates time-consuming tasks like damage assessment and material calculations, enabling technicians to focus more on the repair itself.

Furthermore, integrating tire services, collision repair services, and auto glass repair into a comprehensive direct repair offering allows for better resource allocation and improved customer satisfaction. Efficient inventory management systems also play a crucial role in minimizing downtime, as they ensure that necessary parts are readily available when needed. Ultimately, these strategic optimizations contribute to a more agile and responsive auto body shop, catering to the modern customer’s demand for swift and reliable direct repair services.

In today’s fast-paced world, understanding the efficiency of an auto body shop’s direct repair process is crucial. By optimizing and streamlining various factors, shops can significantly reduce repair times. From initial assessment to final inspection, efficient communication, advanced technologies, and a well-trained workforce are key drivers in expediting direct repairs. With continuous improvements in these areas, auto body shop direct repair is becoming more streamlined, ensuring faster turnaround times for customers without compromising quality.